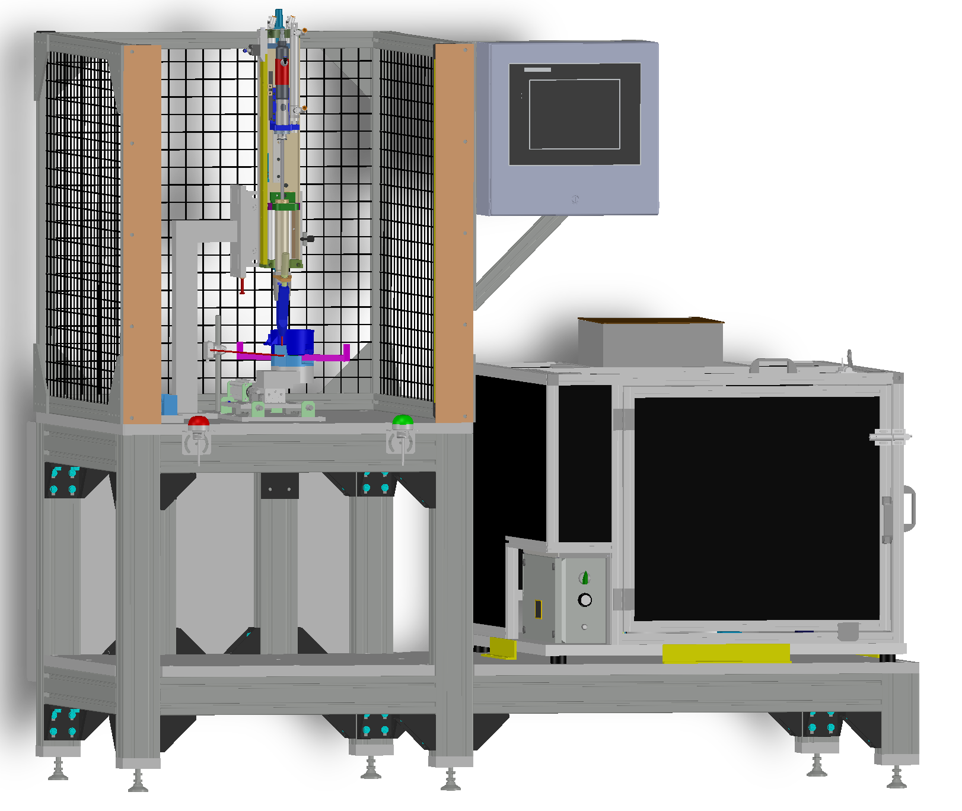

75% reduction in labor with small assembly

This project transitioned a labor-intensive manual process combing two metal brackets with an injection molded part using two screws into a fully automated solution. By boosting efficiency, we reduced operator workload and redirected that capacity toward managing new automated systems

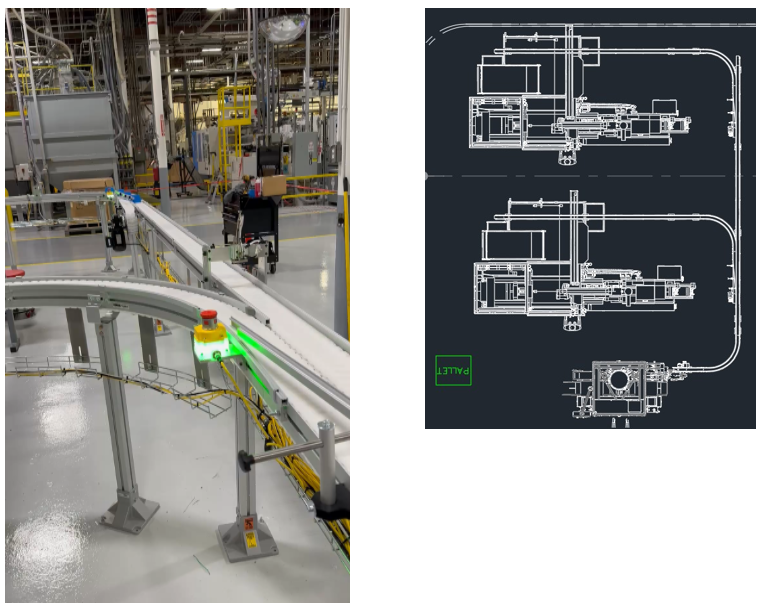

Double Production Output and Reduce WIP by 90% through Integration of Conveyor System between Operations

Optimized production by installing a conveyor system to link two injection molding machines to one automation unit, successfully reducing idle time and boosting overall equipment effectiveness (OEE). The design enables precise control of parts arriving from both injection molding machines to prevent jams. Additionally, it allows the machines to continue placing parts on the conveyor even during automation downtime, which has successfully eliminated 90% of the Work-In-Progress (WIP) that previously accumulated in Gaylords

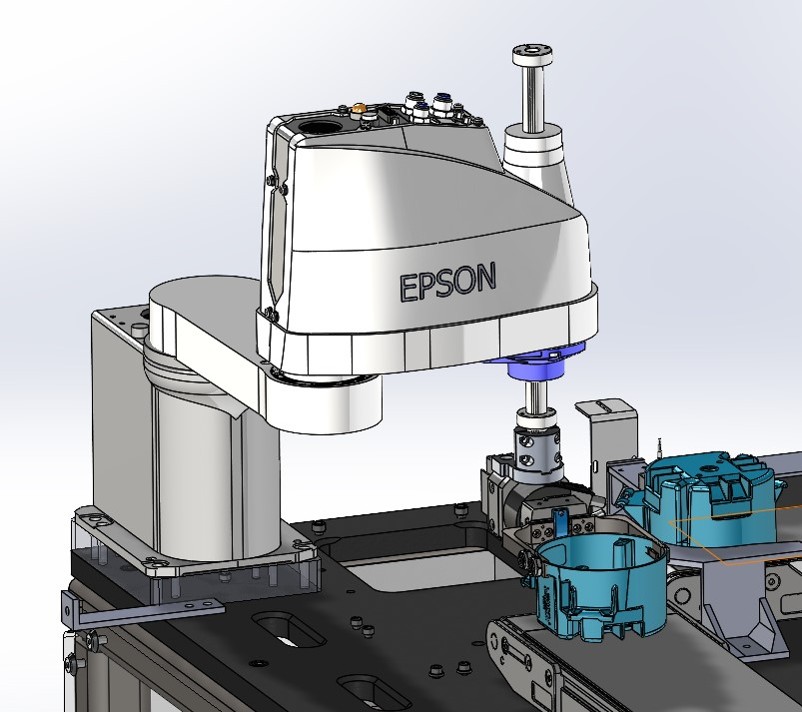

Production increase by 25% and achieving a 5 Month Payback with integration of Epson Cobot

Mitigated a process bottleneck with the use of an Epson robot, achieving a 0.8-second cycle time reduction per part and a 205-part increase in hourly yield. Our strategic design not only increased production capacity but also achieved a five-month payback period, ensuring the project was as financially viable as it was operationally efficient. Additionally, hourly up time was increased by 8% by eliminating parts jamming on incoming conveyors.

Mitigating Label Shortages with Direct-to-Part Inkjet Printing - Under a Second Per Part

By quickly and efficiently integrating 20 Keyence inkjet printers into existing production lines, we successfully bypassed ongoing supply chain issues. Beyond resolving these logistical hurdles, the transition to direct printing significantly reduced the per-unit cost of barcodes compared to traditional paper labels. Additionally, implementing this new technology eliminated the maintenance costs associated with the legacy labeling systems replaced by the inkjet printers

$500k Savings plus WIP Elimination with Minimal Investment Through Automated Buffering System

By installing mechanical gating devices and optimizing the control logic of our existing conveyor system, we enabled four injection molding machines to maintain continuous operation during downstream automation outages. This solution leveraged existing PLC infrastructure with minimal capital investment to drastically reduce WIP accumulation. Previously, all four machines were idled daily due to excessive WIP but following implementation, these shutdowns were reduced to just one or two occurrences per week, vastly improving total system uptime and cost-efficiency.